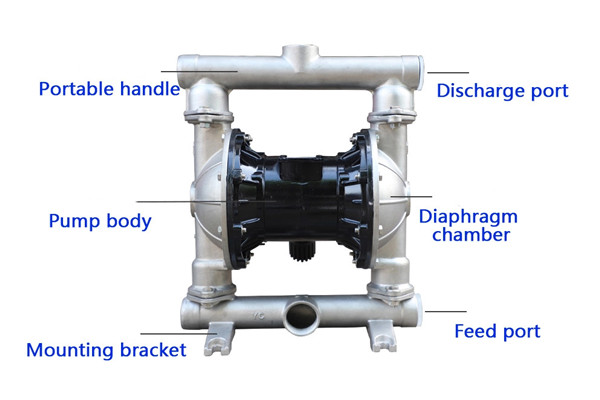

Diaphragm Pump

QBK Series Air Operated Diaphragm Pump

- Inlet&Outlet size:8~80mm

- Body Material:PP/Al/SS304/PVDF

- Diaphragm Material:NBR/PTFE/EPDM

- Connection:Flange/Thread

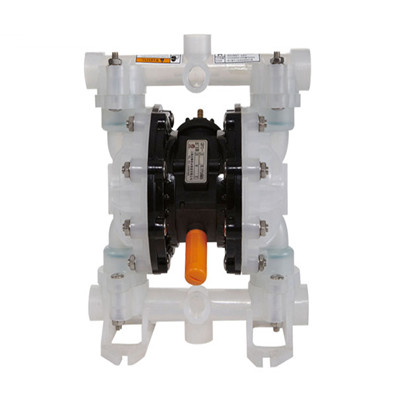

- Product description: PP diaphragm pump

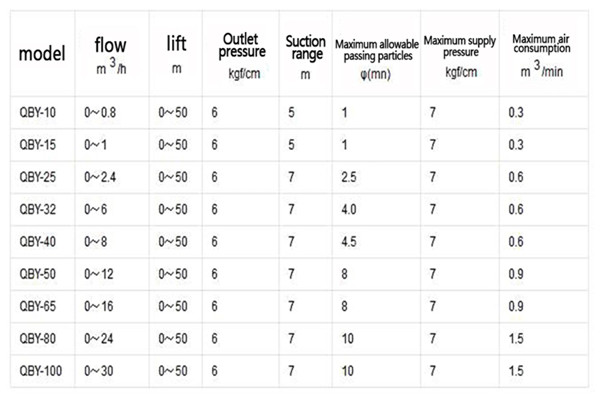

QBY pneumatic diaphragm pump product overview: QBY3 third generation pneumatic diaphragm pump produced by our company is a new type of conveying equipment and a new type of pump in China at present. Using compressed air as the power source, it can absorb all kinds of corrosive liquid, liquid with particles, high viscosity, volatile and flammable liquid.

QBY pneumatic diaphragm pump features: The difference between QBY3 series third generation pneumatic diaphragm pump and traditional diaphragm pump lies in the valve structure. QBY3 series pneumatic diaphragm pump valve structure eliminates the traditional "O" ring and column valve structure of the valve. Three way pilot type is adopted to eliminate valve sticking point and pump shutdown. The correct reversing signal is provided to avoid stop and change direction more quickly, so that the pump has a large flow rate and provides the conveying performance, so that the pulse is small and the flow is stable. QBY3 third generation pneumatic diaphragm pump is designed with simple air reversing valve, which can avoid expensive shutdown cost caused by shutdown. The air valve components can be replaced without removing the fluid part. After other treatment, the aluminum parts can resist the corrosion caused by unclean air. The slide block made of plastic material in the reversing valve is solid and durable, and is not easy to be damaged. The smooth air path and flexible reversing are realized.

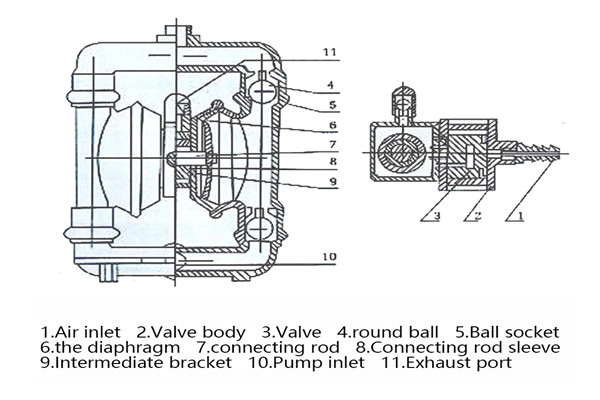

Working principle of QBY pneumatic diaphragm pump In the two symmetrical working chambers of diaphragm pump, there is a piece of elastic diaphragm respectively, and the connecting rod will form two diaphragms into one. After the compressed air enters the air valve chamber from the air inlet connector of the pump, it pushes the diaphragm in a working chamber and drives the diaphragm connected by the connecting rod to move synchronously. At the same time, the gas in the other working chamber is discharged from the back of its diaphragm. When the piston reaches the end of stroke, the valve mechanism will automatically introduce compressed air into another working chamber to push the diaphragm pump to move in the opposite direction, thus forming the synchronous reciprocating motion of the two diaphragms. Each working chamber is equipped with two ball valves. The reciprocating motion of diaphragm causes the change of volume in the working chamber, forcing the two ball valves to open and close alternately, so that the liquid can be continuously inhaled and discharged.

Application scope of QBY pneumatic diaphragm pump: 1. Pumping peanut butter, pickles, mashed potatoes, small red sausage, jam apple pulp, chocolate, etc. 2. Pump paint, gum, pigment. 3. Adhesive and glue, various types can be pumped. 4. All kinds of glaze paste of tile, porcelain, brick and pottery. 5. After the well is drilled, the sediment is pumped and grouted. 6. Pump various emulsions and fillers. 7. Pump all kinds of sewage. 8. Pumps are used for oil tankers and barges are used to absorb the sewage from the tanks. 9. Hops and fermentation powder slurry, syrup, molasses. 10. Pump the water in mine, tunnel, tunnel, mineral processing and slag. Pumping cement grouting and mortar. 11. All kinds of rubber paste. 12. All kinds of abrasives, corrosive agents, oil and mud, cleaning oil dirt and general containers. 13. Various flammable and volatile liquids. 14. All kinds of strong acid, strong alkali, strong corrosive liquid. 15. All kinds of high temperature liquid can withstand 150 โ. 16. It is used as the front stage pressure supply device of various solid-liquid separation equipment.

Categories

Latest News

Contact Us

Contact: Patrick Wang

Phone: +86-15021968128

Tel: 0379-6396 5569

Add: Room 7402,Building 8,No.136 Jinchengzhai Street, Luolong District,Luoyang City,Henan Province

Irene Lee

Irene Lee Patrick Wang

Patrick Wang