Metallic Chemical Process Pump

CP Horizontal Chemical Pump

- Structure: Single-stage Pump

- Theory: Centrifugal Pump

- Material: PPH

- Product description: Horizontal Chemical Pump

Overview

MMCP type is the single-stage horizontal centrifugal pump with SIC/SICA/ITON mechanical seal system.Connected to the driving part by means of a spacer coupling(back-pull-out version)and installed on a common baseplate,the design is fully compliant with standard DIN22858/ISO2858.The metal armouring applied to components made from thermoplastic resins,such as PP,PPH,PVDF,FEP,PEHD,ensures dimensional stability and mechanical strength.MMCP type pump can mount types of single or double mechanical seal of top domestic and international brands.which can work with corrosive liquids containing suspended solids or crystals.Generously-sized shaft,bearings and closed impeller make this series of Hi-Tech Pumps ideally suited for the most demanding process services.

โฒApplications

Because of its remarkable features,plastic MBIM pumps are used in many different industrial sectors.with a wide range of applications, i.e. the following ones:

Chemical Industry: HCI, NaOCI, H2SO4, NaOH, HNO3, HF...

Water treatment: FeCL3,AI2(SO4)3,aluminium polychloride,demineralized water,osmosis sater,membrane cleaning...

Surface treatment: acid degrease, pickling, galvanizing, anodizing ...

Fertilizer industry : H3PO4, H2SO4, H2SiF6, NH4NO3, liquid fertilizer...

Thermal and Nuclear power plants : chlorination of cooling water, neutralization ponds...

Fine chemicals : intermediate products, synthesis reactions, water treatment, cleaning...

Mining: gold, copper, platinum, aluminium, leach liquids...

Sea water: aquariums, fish farms, zoos...

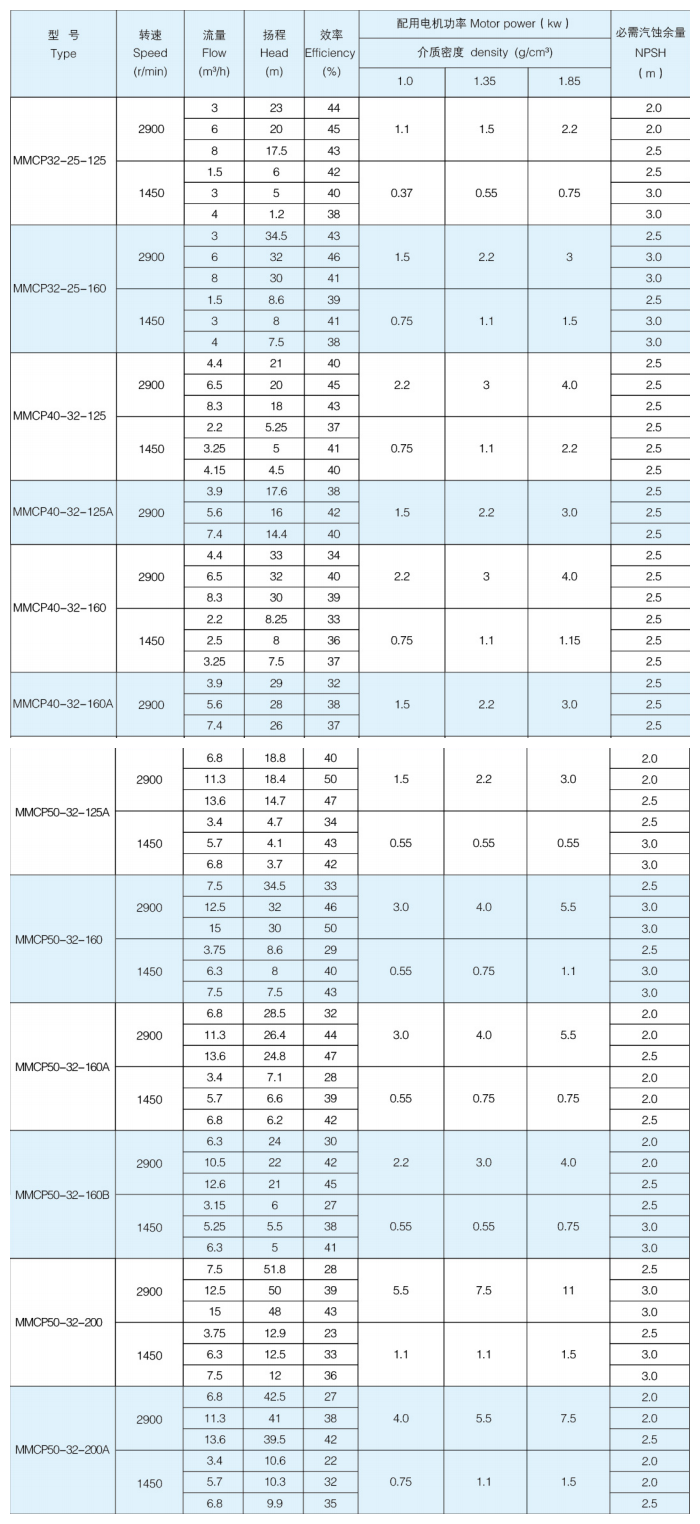

โฒ Performance data for 50/60 Hz operation

Pump capacity [Q] up to 1400m3/h

Total differential head [H] up to 100m

Motor rating [P] up to 200KW

Shaft Seal

Single or double mechanical seal

A Flange connection

Standard design to DIN2501,PN16

Alternatively:- to ANSI B16.5,Class 150,

-toGB/T9116 PN16

โฒ Drive

Three-phase a.c. motor, frame type B3 to IEC, BS or NEMA; type of protection, flameproof enclosure and motor voltage to customer specifications.

โฒ Painting

Corrosion protection of metallic components by multiple coatings of epoxy resin paint

โฒ Design

Chemical Norm Pumps

โฒ Materials

Parts of the pump in contact with the liquid are manufactured from the following standard plastics: Polypropylene PP

Temperature range from 0 Deg.C to+100 Deg.C

High Molecular Polyethylene PE

Temperature range from -50 Deg.C to+80 Deg.C

Polyvinylidene Fluoride PVDF

Temperature range from -20 Deg.C to+130 Deg.C

These materials have been selected as a result of many years of experience in the use of chemical engineering materials,to satisfy the special demands made in pump construction.

โ Maximum safety during operation through use of solid plastic construction.

(5) A sturdy armour in cast iron covering the entire pump casting is to absorb all external forces and torques.

It reduces sound emission and provides increased protection from explosion inside the pump and therefore more safety for operational staff.

(3) Minimum axial thrust and large axial clearances enable clean and dirty liquids to be handled without increased erosive wear.

โฃ Back-pull-out design allows easy accessibility to all parts for maintenance purposes.

โค Operationally safe shaft sealing by using internal single mechanical seal or double mechanical seals with external flushing .

Categories

Latest News

Contact Us

Contact: Patrick Wang

Phone: +86-15021968128

Tel: 0379-6396 5569

Add: Room 7402,Building 8,No.136 Jinchengzhai Street, Luolong District,Luoyang City,Henan Province

Irene Lee

Irene Lee Patrick Wang

Patrick Wang