Vertical Sump Pump

CYP Vertical Chemical Pump

- Structure: Single-stage Pump

- Material: PVDF PP PPH

- Theory: Centrifugal Pump

- Product description: Vertical Chemical Pump

CYP corrosion resistant vertical is independently designed by the company with unique process.It is a new energy-saving pump with low suction depth and strong anti-corrosion performance. This series of products have reliable performance, beautiful appearance ,stable operation,light weight,small vibration, low noise, convenient assembly and disassembly and small land area,especially the pump is submerged in the liquid without irrigation if fluid and without shaft seal leakage. Excellent application performance is admired by petroleum,chemical, pharmaceutical,paper making ,dyeing, metallurgy, environmental protection, and pesticide industries.

MMCP vertical pump has the following characteristics:

1) All of the parts in contact with the liquid are used with plastic PVDF or PP,PPH,which have excellent chemical resistance.

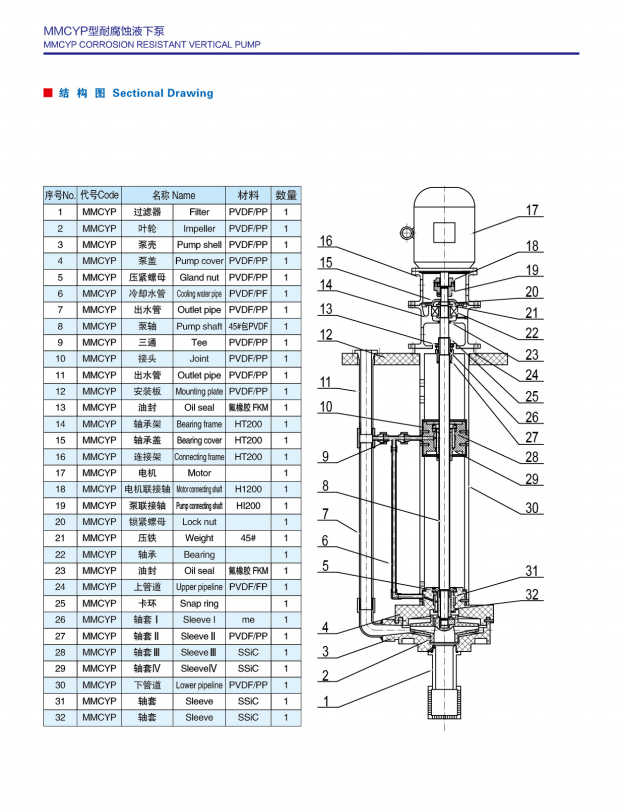

2) Pump shell is made with whole plastic molding,pump shaft uses 45# steel heat treatment and covered with 3mm PVDF or PP,PPH.In order to ensure stable operation of the pump shaft,a support seat is provided between the support tube (PVDF or PP,PPH plastic pipe)and pump shaft. Inside the support seat there is a SSIC sleeve in order to ensure normal operation of the shaft.At the bottom there is a filter to prevent solid impurities from entering pump.It is made of PVDF or PP,PPH.The outlet pipe is made of pure PVDF and PP,PPH,pipe wall thickness is greater than or equal to 5mm,mounting plate is made of 50mm thick PP board so as to prevent corrosion caused by corrosive medium. Pump shaft is connected with the impeller,which is also made by mould pressing of PP or PPH,PVDF.In the middle there is a metal insert to ensure impeller strength. Finished impeller must pass dynamic balance test.SSIC is installed between the pump shaft and the pump shell.

3) If the transmission medium has high solid content,an additional configurable flushing system may be installed to ensure that the support seat sleeve cannot be damaged.

4) All parts are required to carry out size test, which also need to be tested by 20KV DC high-voltage electric spark test without any breakdown.The transmission parts (including impeller,pump coupling).Motor coupling may be installed are dynamic balance test.A test bench is used to test performance of the pump to confirm the pump performance meets the requirements.It is qualified after 48 hours of continuous operation.

5) Standard seals (including gaskets,O-ring,etc.)are used in the products, including SS304 graphite wound gaskets and imported fluorinated rubber made O-ring.All fasteners not contact with the transmission medium are made of SS304 standard stainless steel parts.

Categories

Latest News

Contact Us

Contact: Patrick Wang

Phone: +86-15021968128

Tel: 0379-6396 5569

Add: Room 7402,Building 8,No.136 Jinchengzhai Street, Luolong District,Luoyang City,Henan Province

Irene Lee

Irene Lee Patrick Wang

Patrick Wang